Airbag Wiring Harness

Sewon Electronics will endeavor to be the best.

- Airbag Wiring Harness

- This is a wiring system that delivers power and signals from a passive safety device designed to automatically inflate airbags to protect passengers thrown forward in the event of a collision.

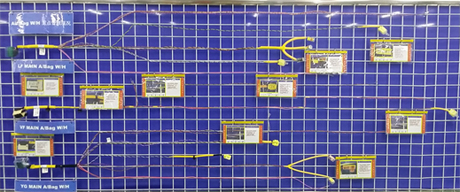

Airbag wiring manufacturing process

Material input

-

Material import inspection process

When parts are received, the quality of the items subject to inspection is checked.

-

Material warehouse status (wires/terminals/etc)

When the quality inspection of the material is completed, it is moved to the material warehouse, separated by item and stored on the loading shelf.

Cutting and pressing process

-

Automatic cutting and pressing process

1. This is a fixing work that can prevent corrosion and breakage of terminals or wires by mechanically compressing and fixing the wires by an applicator without using soldering or welding to the terminals.

2. It cuts the wire automatically according to the user input value, strips the sheath, and automatically performs the existing manual work, thus reducing a lot of work time.

-

Manual pressing process

This is a method of mechanically crimping and fixing the stripped wire by an applicator without using soldering or welding to the terminal. It does not provide the function of cutting the wire or stripping the sheath of the automatic crimp machine.

-

Taping process

Semi-automatically taps the joint crimped area.

-

Twist process

It is a device that twists two wires together and reduces signal interference caused by strong radio sources nearby.

-

Gate inspection process

Inspect various defects of products that have been cut and pressed.

Assembly and inspection process

-

SUB assembly process terminal insertion inspection circuit + structure inspection airtightness inspection

In the SUB process, use the less terminal insertion detection equipment to check the misalignment of the terminal and whether the terminal is less inserted into the housing. Inspect the sealing function of and waterproof CONNECOR.

-

Storage of finished products

Products that pass inspection are moved to the storage location for finished products after packaging.